- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ZX-TG800

ZHONGXIN

8477800000

ZHONGXIN AUTOMATIC SIDE SEAING SOFT LOOP HANDLE ZIPPER BAG MAKING MACHINE

Brief introduction:

The machine adopts the advanced Taiwan wellen touch operating system. The raw material directly produce to the bag through automatic deviation correction, folding, bottom insertion, top folding, heat sealing,adding soft loop handle,side sealing and discharging. It has the practical functions of photoelectric rectification, magnetic powder automatic tension,automatic counting, no material automatic stop, electric eye tracking any length, failure automatic alarm and so on.It is one of the most advanced plastic bag making equipment on the market.

Feature:

(1)The tension of raw materials can be adjusted automatically during the operation of the machine.(The automatic tension control system is used for feeding)

(2)The machine adopts pneumatic feeding, which is convenient and simple, and the air pressure can be adjusted.

(3)The machine adopts pneumatic traction rod, which make feeding more smoothly.

(4)Servo no stretch,the heat sealing is flat and good-looking.

(5)Full servo drive, make machine running stablely.

(6)It is equipped with automatic counting (bag making counting or soft loop handle counting),which can automatically calculate during operation.

(7)The conveying table adopts frequency conversion speed regulation to make the discharging more orderly and stable.

(8)There's a water cooling device on the edge of the heat sealing knife to make material more flat and firm.

Technical parameter:

| Bag width | 250-600mm |

| Bag length | 250-700mm |

| Top folding | 50-75mm |

| Bottom inserting | 30-70mm |

| Handle length | 330-370mm |

| Max. unwinding width | 1600mm |

| Speed(handle) | 60-100pcs/min |

| Speed(D-cut) | 70-110pcs/min |

| Power supply | 380V/50Hz |

| Total power | 7.5Kw |

| Dimension | 9200x2500x2050mm |

| Weight | 5000kg |

2. Sample Bag

3. Detials

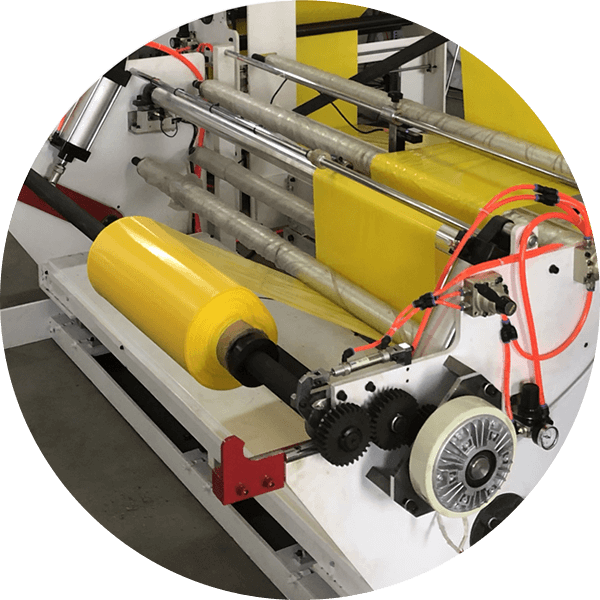

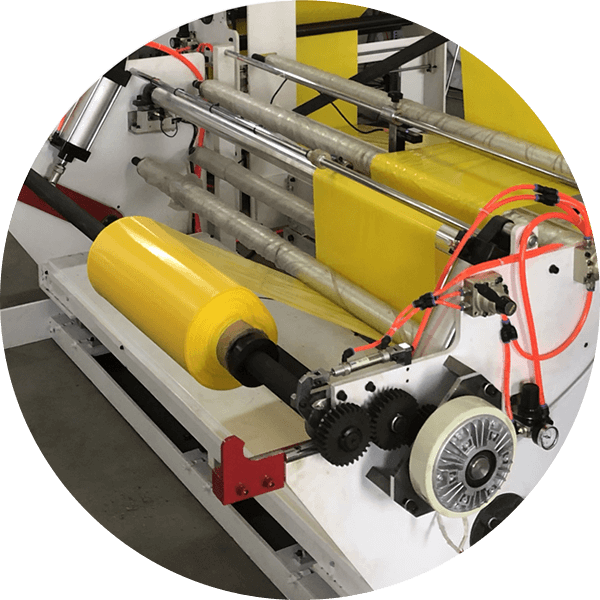

Feeding / Correcting

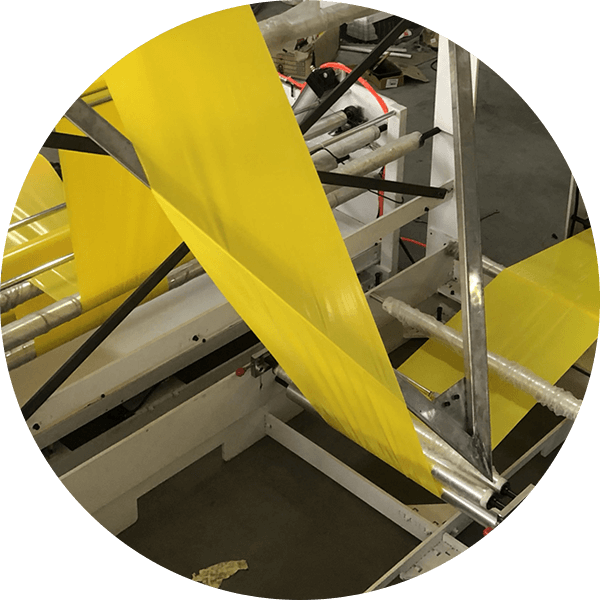

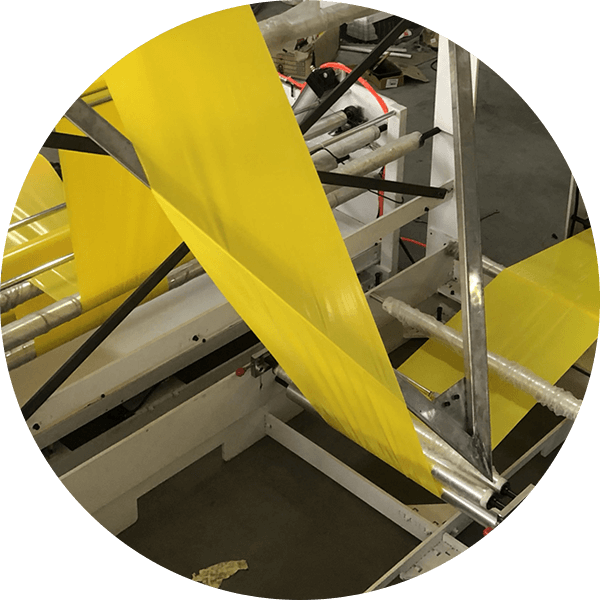

Folding

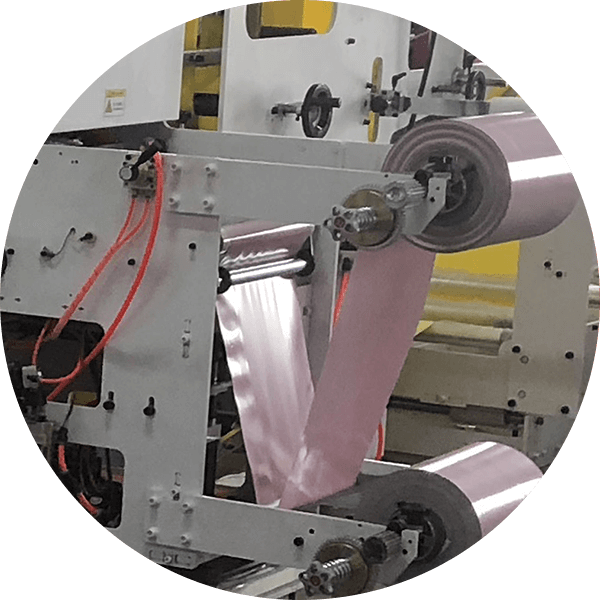

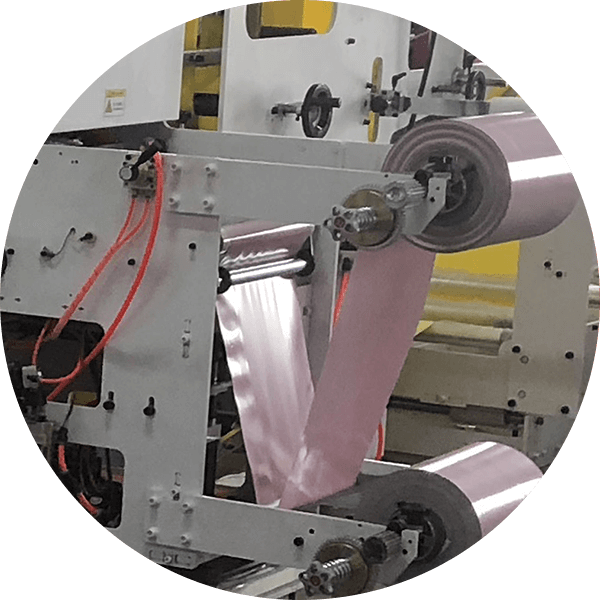

Bottom sealing

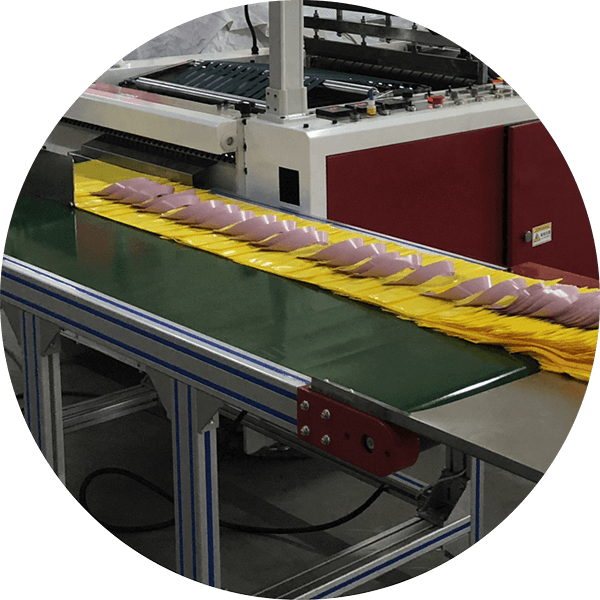

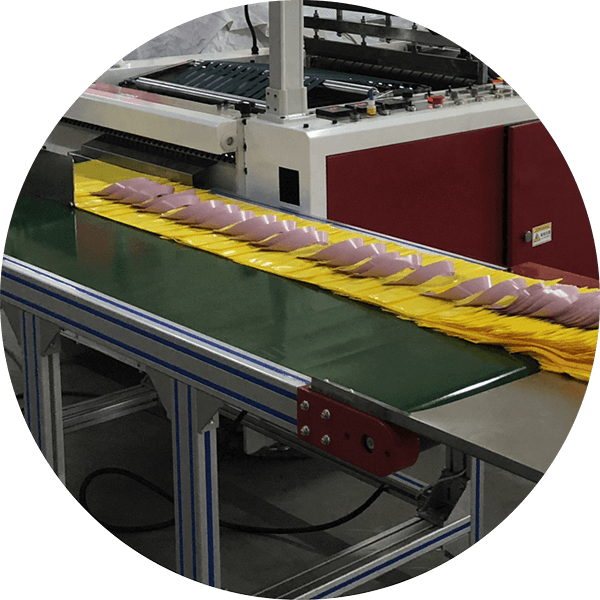

Handle Adding

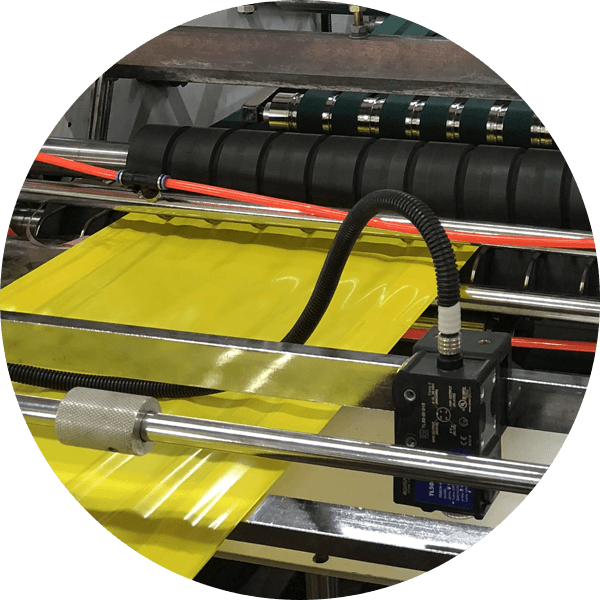

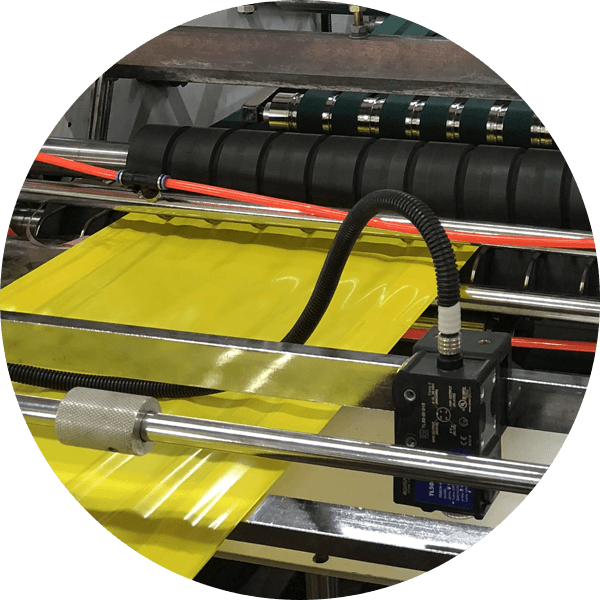

Heat Sealing

Container

4. Certificate

5. Packing

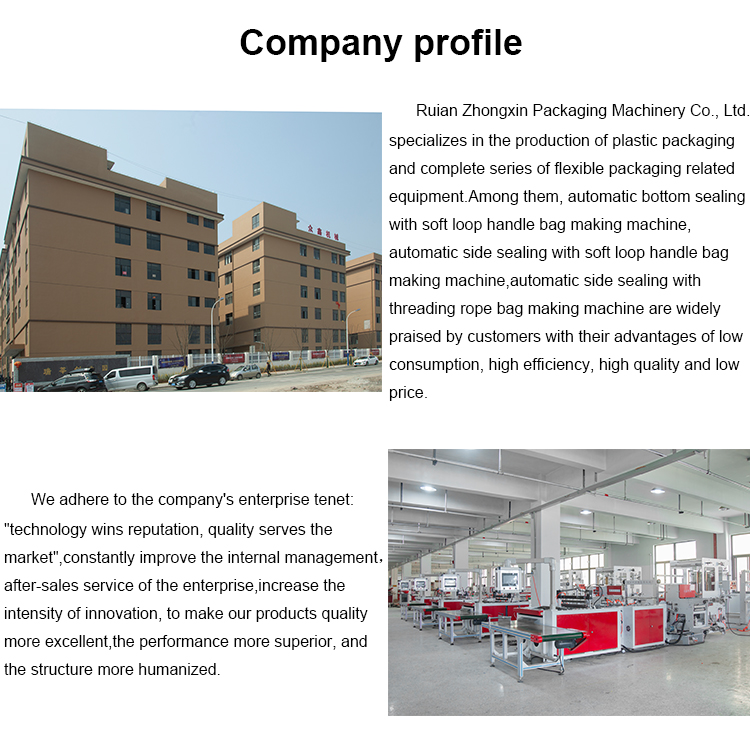

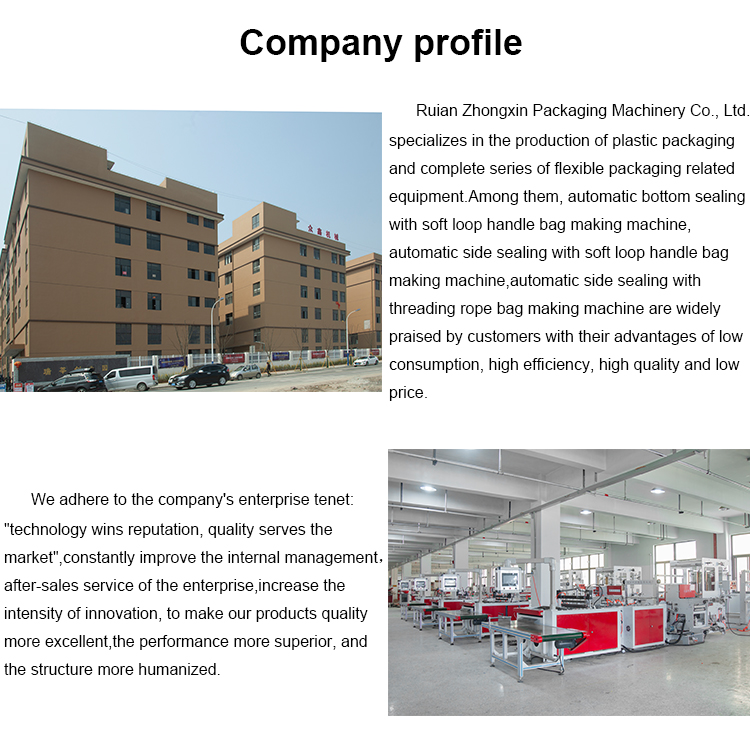

6. About Us

7. FAQ

1) Is your company a factory or a trading company?

We are a factory.

2) Where is your factory? How can i visit your company?

Our factory is located in Ruian, Zhejiang Province, China.

3) What is the suitable material for your machines?

PE, OPP, laminated material ,etc are suitable for our machines

4) What kind of machine do you have ?

We are specializing in manufacturing handle plastic bag making machine.

ZHONGXIN AUTOMATIC SIDE SEAING SOFT LOOP HANDLE ZIPPER BAG MAKING MACHINE

Brief introduction:

The machine adopts the advanced Taiwan wellen touch operating system. The raw material directly produce to the bag through automatic deviation correction, folding, bottom insertion, top folding, heat sealing,adding soft loop handle,side sealing and discharging. It has the practical functions of photoelectric rectification, magnetic powder automatic tension,automatic counting, no material automatic stop, electric eye tracking any length, failure automatic alarm and so on.It is one of the most advanced plastic bag making equipment on the market.

Feature:

(1)The tension of raw materials can be adjusted automatically during the operation of the machine.(The automatic tension control system is used for feeding)

(2)The machine adopts pneumatic feeding, which is convenient and simple, and the air pressure can be adjusted.

(3)The machine adopts pneumatic traction rod, which make feeding more smoothly.

(4)Servo no stretch,the heat sealing is flat and good-looking.

(5)Full servo drive, make machine running stablely.

(6)It is equipped with automatic counting (bag making counting or soft loop handle counting),which can automatically calculate during operation.

(7)The conveying table adopts frequency conversion speed regulation to make the discharging more orderly and stable.

(8)There's a water cooling device on the edge of the heat sealing knife to make material more flat and firm.

Technical parameter:

| Bag width | 250-600mm |

| Bag length | 250-700mm |

| Top folding | 50-75mm |

| Bottom inserting | 30-70mm |

| Handle length | 330-370mm |

| Max. unwinding width | 1600mm |

| Speed(handle) | 60-100pcs/min |

| Speed(D-cut) | 70-110pcs/min |

| Power supply | 380V/50Hz |

| Total power | 7.5Kw |

| Dimension | 9200x2500x2050mm |

| Weight | 5000kg |

2. Sample Bag

3. Detials

Feeding / Correcting

Folding

Bottom sealing

Handle Adding

Heat Sealing

Container

4. Certificate

5. Packing

6. About Us

7. FAQ

1) Is your company a factory or a trading company?

We are a factory.

2) Where is your factory? How can i visit your company?

Our factory is located in Ruian, Zhejiang Province, China.

3) What is the suitable material for your machines?

PE, OPP, laminated material ,etc are suitable for our machines

4) What kind of machine do you have ?

We are specializing in manufacturing handle plastic bag making machine.

Technical Parameter | ||||

| Bag width | 250-600mm | |||

| Bag length | 250-700mm | |||

| Top folding | 50-75mm | |||

| Bottom inserting | 30-70mm | |||

| Handle length | 330-370mm | |||

| Max. unwinding width | 1600mm | |||

| Speed | 50-70pcs/min | |||

| Power supply | 380V/50Hz | |||

| Total power | 7.5Kw | |||

| Dimension | 9200x2500x2050mm | |||

| Weight | 5000kg | |||

Main Configuration | ||||

| Touch screen | Taiwan Weinview | |||

| Electronic valve | Taiwan | |||

| Proximity switch | Schneider | |||

| Cylinder | Taiwan AirTAC | |||

| Photoelectricity | Italy datalogic | |||

| Servo motor | DELTA | |||

| Switching power supply | Schneider | |||

| Note:All configurations can be changed according to the needs of customers. | ||||

Technical Parameter | ||||

| Bag width | 250-600mm | |||

| Bag length | 250-700mm | |||

| Top folding | 50-75mm | |||

| Bottom inserting | 30-70mm | |||

| Handle length | 330-370mm | |||

| Max. unwinding width | 1600mm | |||

| Speed | 50-70pcs/min | |||

| Power supply | 380V/50Hz | |||

| Total power | 7.5Kw | |||

| Dimension | 9200x2500x2050mm | |||

| Weight | 5000kg | |||

Main Configuration | ||||

| Touch screen | Taiwan Weinview | |||

| Electronic valve | Taiwan | |||

| Proximity switch | Schneider | |||

| Cylinder | Taiwan AirTAC | |||

| Photoelectricity | Italy datalogic | |||

| Servo motor | DELTA | |||

| Switching power supply | Schneider | |||

| Note:All configurations can be changed according to the needs of customers. | ||||

The tension of raw materials can be adjusted automatically during the operation of the machine. (The automatic tension control system is used for feeding).

The machine adopts pneumatic feeding, which is convenient and simple, and the air pressure can be adjusted.

The machine adopts pneumatic traction rod, which make feeding more smoothly.

Servo no stretch,the heat sealing is flat and good-looking.

Full servo drive, make machine running stablely.

It is equipped with automatic counting (bag making counting or soft loop handle counting),which can automatically calculate during operation.

The conveying table adopts frequency conversion speed regulation to make the discharging more orderly and stable.

There's a water cooling device on the edge of the heat sealing knife to make the material more flat and firm.

The tension of raw materials can be adjusted automatically during the operation of the machine. (The automatic tension control system is used for feeding).

The machine adopts pneumatic feeding, which is convenient and simple, and the air pressure can be adjusted.

The machine adopts pneumatic traction rod, which make feeding more smoothly.

Servo no stretch,the heat sealing is flat and good-looking.

Full servo drive, make machine running stablely.

It is equipped with automatic counting (bag making counting or soft loop handle counting),which can automatically calculate during operation.

The conveying table adopts frequency conversion speed regulation to make the discharging more orderly and stable.

There's a water cooling device on the edge of the heat sealing knife to make the material more flat and firm.